With the development of industrialization, water treatment has been applied in all walks of life. In this process, flocculants, as excellent industrial water treatment chemicals, play an important role. Flocculants can effectively gather suspended matter and fine particles in water, and improve the effect and efficiency of water treatment. Then, what is the most effective flocculant in water treatment? This article can help a lot.

What is a Flocculant?

The flocculant is an industrial water treatment chemical, which helps remove suspended solids from water. It works by aggregating small particles to form larger flocs, making them easier to settle or filter. In industrial water treatment process, flocculants are widely used, especially in municipal sewage, industrial wastewater and drinking water. By using appropriate flocculants, the impurities in the water can be effectively reduced, thus ensuring that the treated water meets the required quality standards.

Common Types of Flocculants

According to the chemical composition and mechanism of action, flocculants are mainly divided into the following categories:

Organic Flocculants

Organic flocculants are usually made of polymer chemicals that form strong floc groups with suspended substances in water. They typically have long molecular chains that can bind to particles in water through physical adsorption or chemical reactions, allowing these particles to form larger clumps for easy settlement or filtration.

polyacrylamide (PAM)

In industrial water treatment chemicals, polyacrylamide (PAM) is a common organic flocculant that is widely used in various industrial water treatment processes, especially in wastewater treatment, wastewater recovery and mineral treatment. PAM flocculants come in many types, including anionic, cationic and non-ionic, in two forms, solid or emulsion. PAM reacts with suspended matter in water through its polymer structure to aggregate and promote the formation of large floc of these suspended particles, which is easy to settle and filter.

Note: Because Anionic PAM (APAM) has the issue of residual monomer, only APAM that has obtained NFS certification can be used for tap water treatment, while Cationic PAM (CPAM) cannot be used for tap water treatment.

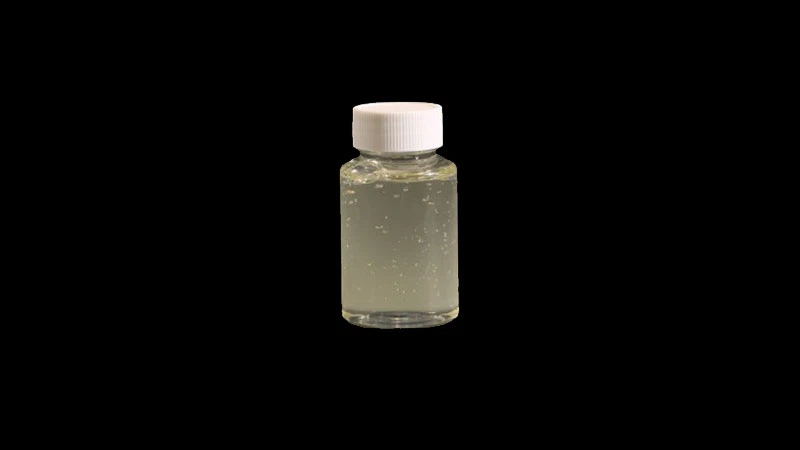

Polydadmac (PDADMAC)

Polydadmac (PDADMAC) is widely used as a flocculant in drinking water treatment, wastewater treatment and mining processes. Through charge neutralization and adsorption bridging mechanisms, PDADMAC destabilizes and flocculates suspended particles and negatively charged aqueous substances in water. It has remarkable effects in decolorization, algae killing and removal of organic matter. Similarly, the PDADMAC with NSF certification can be used for drinking water treatment.

Polyamine (PA)

Poly(EPI-DMA), namely Polyamine (PA), is also an organic flocculant with excellent performance. When PA is used as a flocculant, its mechanism is electro-neutralization and adsorption bridging. Similarly, PA flocculants with NSF certification have a wide range of applications in drinking water treatment, especially with Polyaluminum Chloride (PAC).

Inorganic Flocculants

Inorganic flocculants are usually made of metal salts and have strong electrolytic reaction ability. When these flocculants dissolve in water, they release charged ions that neutralize the charge of the particles suspended in the water, thus encouraging the particles to aggregate into larger flocs. Common inorganic flocculants include Polyaluminum Chloride (PAC), Aluminum Sulfate, Ferric Chloride and so on.

- Polyaluminum Chloride (PAC) is an efficient inorganic flocculant, which is widely used in water treatment. It can effectively remove suspended matter, colloidal matter and organic pollutants in water through powerful electrolytic action and excellent flocculation performance. Polyaluminum chloride chemical is suitable for the treatment of drinking water, industrial wastewater, sewage and swimming pool water, with the advantages of low dose, high efficiency and environmental friendliness.

- Aluminium Chlorohydrate (ACH), similar to PAC, has superior charge neutralization ability and is a powerful coagulant and flocculant.

- Aluminum Sulfate (Alum): Alum is a traditional flocculant that has been used for decades. It is effective in treating drinking water and wastewater, but its use has declined due to the availability of more effective alternatives.

- Ferric Chloride: This inorganic flocculant is commonly used in wastewater treatment plants. It also effectively removes phosphates and heavy metals from water.

Composite Flocculants

Composite flocculants combine the advantages of organic and inorganic flocculants, made by combining two or more different types of flocculants. They can be adjusted according to water quality characteristics and treatment requirements, so as to obtain better flocculation effect. The composite flocculant can improve the efficiency and effect of water treatment by synergistic action.

In addition, natural polymers such as starch, chitosan and other biodegradable materials can also be used as flocculants. They are environmentally friendly, but generally not as effective as synthetic flocculants such as PAM flocculant.

What is the most effective water treatment flocculant?

Then among these excellent industrial water treatment chemicals, which flocculant is the most effective? The answer to this question is not simple. Each flocculant has its own advantages, and the choice is determined by many factors. Specific aspects are as follows:

Flocculation Effect

Flocculation effect is the primary factor in selecting flocculant. Generally speaking, the flocs formed by PAM flocculant is tight, and its flocculation effect is the most significant. However, PAC chemical also has excellent flocculation effect when dealing with water quality problems, especially in water with large turbidity and high concentration of suspended matter.

Water Quality Features

The different characteristics of water quality are also the factors for selecting flocculants. The types and concentrations of suspended substances, colloidal substances, organic pollutants and inorganic substances in water, as well as the pH value, hardness and temperature of water, will directly affect the effect of flocculants.

For organic substances with strong viscosity, it is usually necessary to select organic flocculants with strong adsorption capacity, such as PAM flocculant. For water with more inorganic substances, the use of inorganic flocculants such as alum or polyaluminum chloride may be more effective.

In addition, different flocculants are sensitive to different pH values. Organic flocculants are generally effective over a broad pH range, while inorganic flocculants may perform better over a specific pH range.

Cost Consideration

When selecting flocculants, it is also necessary to consider its economy. In general, PAC and Alum are usually less expensive, suitable for large-scale water treatment, and more economical for treating water bodies with simple water quality or high suspended matter concentration. In contrast, organic flocculants, such as PAM flocculant, although more expensive, because of their efficient flocculation effect, usually require less dosage. Besides, less sludge is produced when organic flocculants are used. They can reduce the cost of use and are more cost-effective in the long run, especially in the treatment of complex water quality. Of course, the final cost comparison should be estimated through Jar Test and determined through trial runs.

Processing Target

Different water treatment targets also affect the choice of flocculants. For example, for drinking water treatment, flocculants must not only efficiently remove suspended matter, but also meet strict environmental protection and safety standards to avoid secondary pollution. In industrial wastewater treatment, more emphasis may be placed on treatment efficiency and cost control, especially for wastewater containing oil or heavy metals. In this case, specific flocculants may need to be selected to ensure the best results. If you need flocculants, whether PAM, PAC, Alum or other flocculants, welcome to contact us. Our team will recommend suitable models and cost-effective flocculant products according to your treatment targets.

Operating Condition

Different types of flocculants are also different in the mode of operation, mainly reflected in the dosing method, mixing reaction time, use conditions and so on. Inorganic flocculants such as PAC require simple operation and are easy to use, while organic flocculants such as PAM flocculant have higher dosing and dissolution conditions and complex operation.

Applications of Different Flocculants

It can be seen that the selection of flocculants is determined by multiple factors. We will choose to use different flocculants based on different water quality conditions. Let's take a look at the following cases.

Municipal Sewage Treatment

In municipal wastewater treatment, flocculants are used to remove suspended solids and colloidal substances from water. PAC is often used in the primary and secondary treatment of municipal sewage, which can effectively gather suspended particles to form larger floc and accelerate the settlement process. For more complex pollutants, PAM flocculants play a good role, especially in the case of poor water quality, improving the efficiency of water treatment.

Industrial Wastewater Treatment

In the industrial water treatment process, PAM flocculant is widely used in the purification of various industrial wastewater, especially in mining, chemical, paper and metallurgy industries. Because PAM flocculant can quickly collect suspended solids in water, it is widely used to reduce pollutant discharge and improve the recyclability of water.

Drinking Water Purification

Inorganic flocculants such as PAC, ACH and Alum are often used in the drinking water treatment process to remove cloudy substances and improve water quality. The transparency and taste of water can be improved effectively by selecting suitable flocculants.

In addition to municipal sewage, industrial wastewater and drinking water treatment, there are many water treatment scenarios where flocculants are needed, such as:

|

Water Treatment Type |

Scenario |

Flocculants Type |

Processing Features and Effects |

|

Aquaculture wastewater treatment |

The drainage from fish ponds, shrimp ponds, etc. contains feed, feces and suspended matter |

PAC, CPAM |

Rapidly flocculate and settle organic impurities to improve water quality and prevent eutrophication of water bodies |

|

Mining wastewater treatment |

Coal washing wastewater, tailings water, etc |

APAM, PAC, Polyferric Sulfate (PFS) |

Promote the sedimentation of mine sludge, reduce solid suspended matter and increase water reuse rate |

|

Food wastewater treatment |

Organic wastewater from beer, dairy products, soy sauce factories, etc |

APAM, PAC, composite polymer flocculant |

Remove colloidal organic substances such as proteins and oils, and reduce COD and BOD |

|

Textile wastewater treatment |

Wastewater from dyeing and printing factories and garment factories contains high chroma and heavy organic load |

PAC, PFS, CPAM |

It has a good decolorization effect, enhances flocculation and sedimentation, and improves the efficiency of biochemical treatment |

|

Circulating cooling water or boiler water |

Industrial circulating water system |

APAM, PAC |

Remove scale and suspended particles to extend the service life of equipment |

Also read: How to Treat Aquaculture Wastewater

To sum up, different flocculants have different advantages in the water treatment process. Whether polyacrylamide, polyaluminum chloride, alum, ferric chloride or other flocculants, they need to be comprehensively considered according to the characteristics of water quality, treatment targets and cost effectiveness. We are a professional supplier of industrial water treatment chemicals with over 14 years' sufficient real-field experience. If you need chemicals for coagulation and flocculation, welcome to contact us!